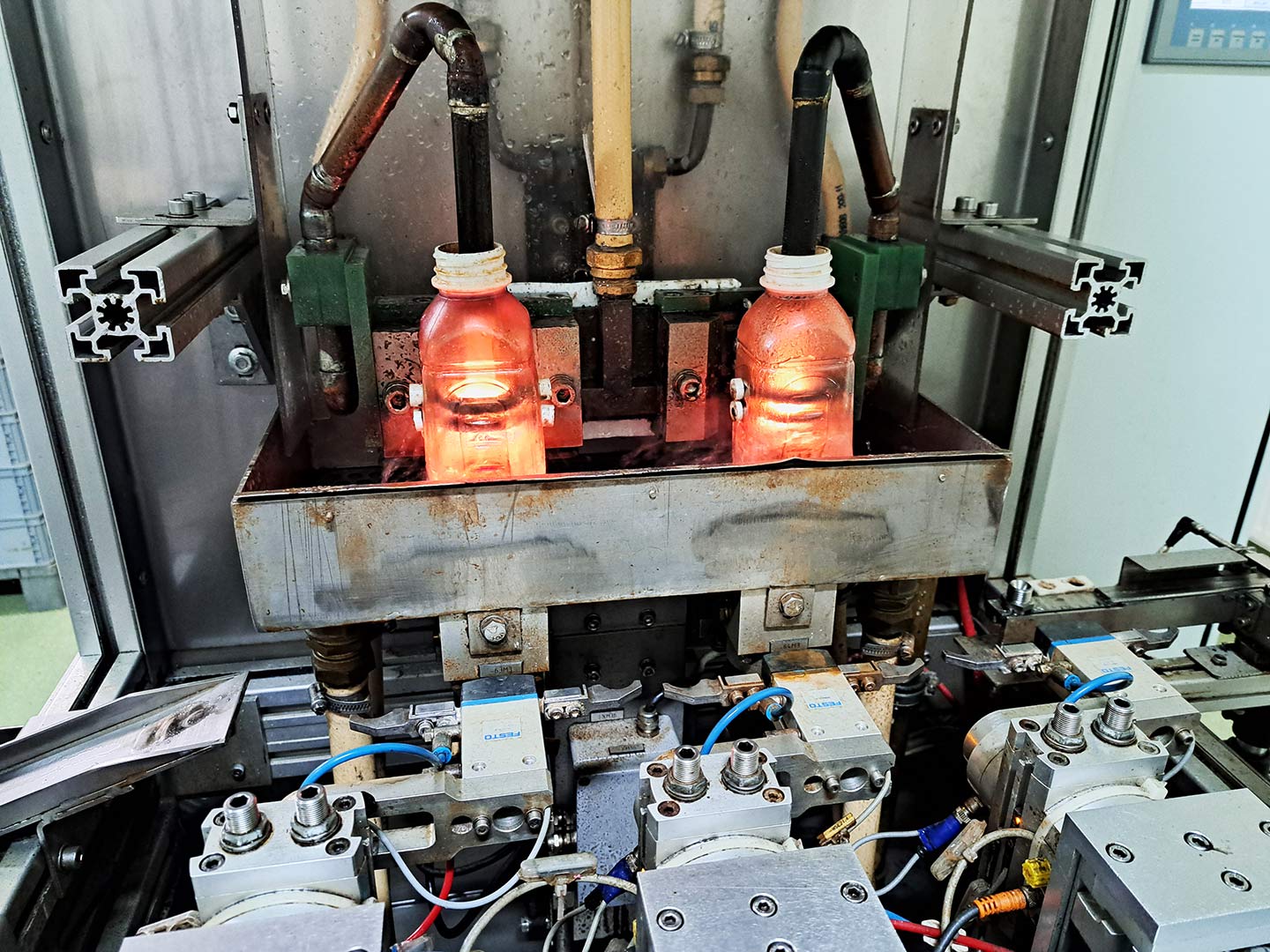

Induction hardening is carried out on fully automated CNC controlled multi-spindl and rotary tabled equipments. A constant, stable temperature of the coolant / cooling liquid is ensured by automatic control and system integration. During series setups a cross-sectional grind is made for the first and last parts, the conformity is checked with additional inter-production measurements, and the approval is done with final product inspection.

Quality assurance and Quality control

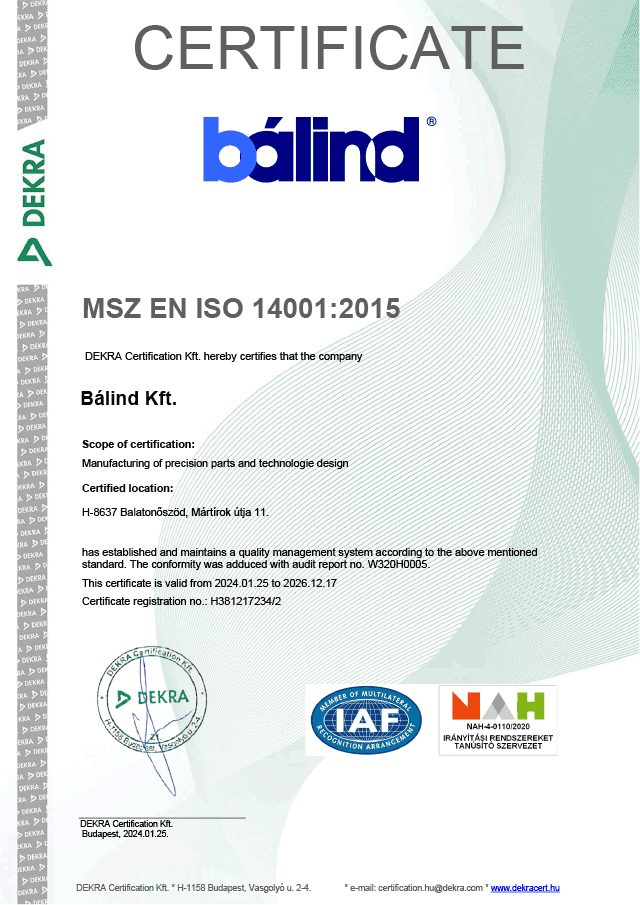

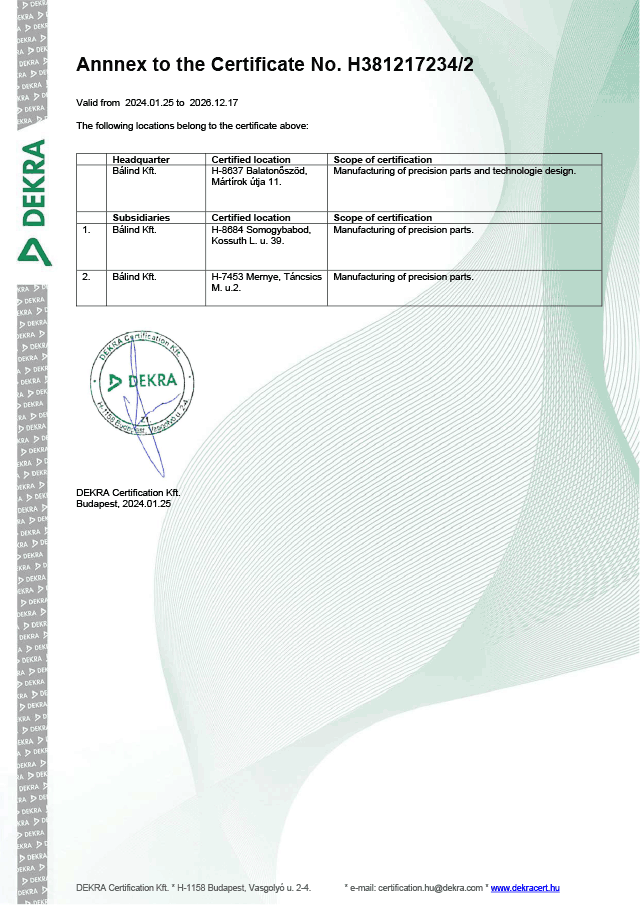

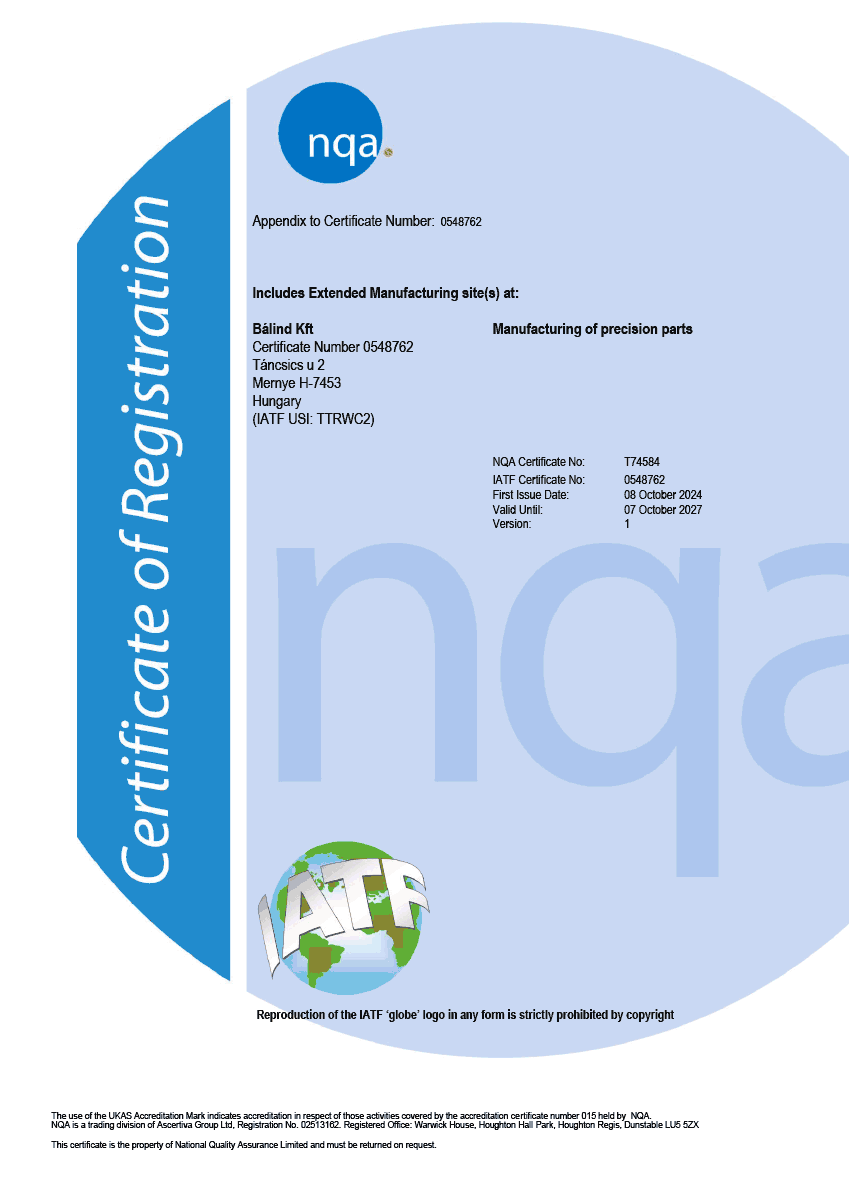

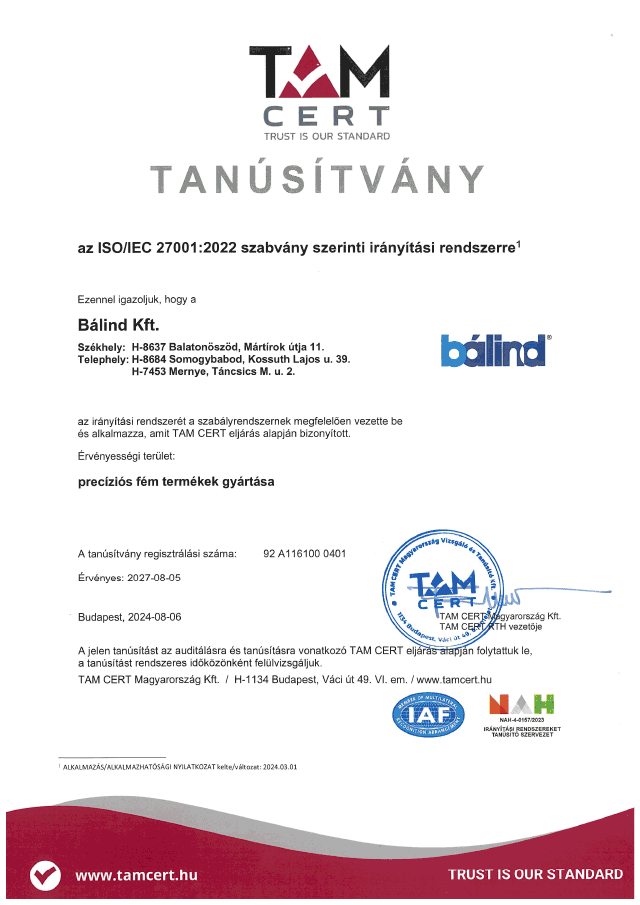

Our company operates certified systems according to IATF 16949:2016, ISO 9001/2015, 14001:2015 and ISO 27001/2022 as well as NIS2 and TISAX standard requirements.

Laboratory | Tests

The following tests can be performed in the quality laboratory of our company::

Surface hardness measurements:

- Rockwell (HRA, HRC)

- Vickers (HV10, HV30, HV50, HV150)

- Brinell (HB 3–200)

- Preparation of grindings / core hardness and hardness gradient measurements on grinding (HV1)

- Microscopic metallographic examinations

We issue an MSZ EN 10204:2005 3.1 quality certificate for our service.

Our other related services

- Magnetic and penetration crack tests

- Deformation-like (100%) optical and geometric measurements resulting from heat treatment technology

- Automated straightening and Ultrasonic crack testing (for axle-type parts)

If required, we provide Control Plan and FMEA documentation and PPAP documentation for the products.